Over 2000 new artificial turf fields are being installed every year in the United States. Each one of these fields require 120 tons of crumb rubber infill. Although the Environmental Protection Agency touted this downcycled, re-use methodology for their problem with tire disposal, it is simply a band-aid for the larger problem. That material will end up in a landfill or worse, in our waterways. The artificial turf industry has evolved and developed systems that embrace environmental sustainability and it’s time for all of us – parents, owners, athletes, designers, and turf representatives – to adopt these innovative practices.

Brock USA led the way in sustainable design with the first Cradle to Cradle certified product in the industry. The engineering team understood that a product must have a responsible end-of-life solution in order for it to become sustainable. The Brock shock pads produced 15 years ago are now under fields that are on their second turf life and, according to simulated 100-year testing, will last many more turf replacements. Any artificial turf shock pad damaged during the turf removal and replacement process can be locally recylced or shipped back to our manufacturing plant, washed, ground up, and melted back to its original form to become a new pad for a new artificial turf field. This is the moral foundation for Brock USA and how the company approached solving the crumb rubber crisis.

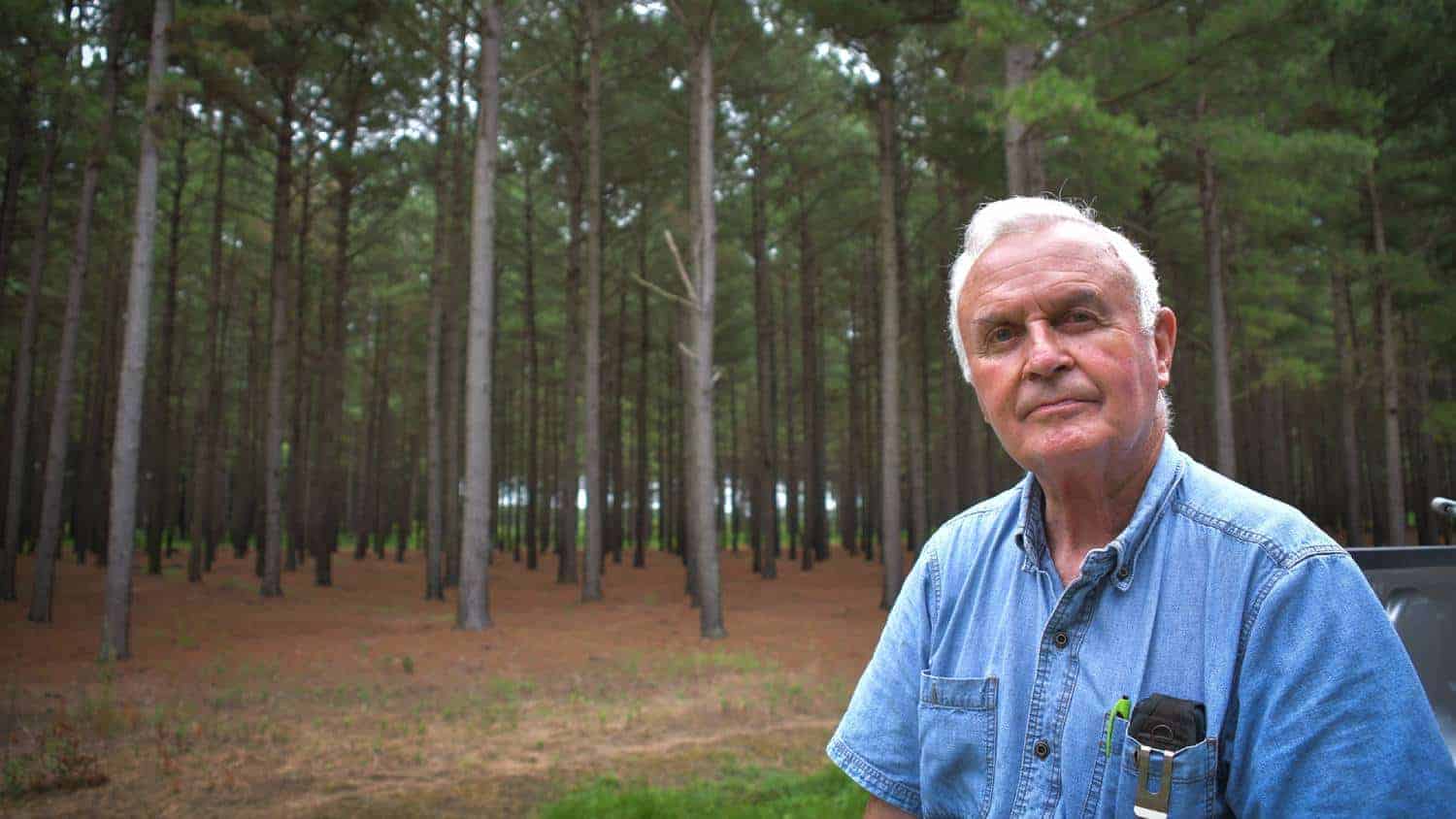

By starting from the end, Brock’s engineers knew that the ideal infill to supplant crumb rubber had to have an environmentally responsible end of life plan. Organic materials held the best promise for achieving this goal, so identifying what organic infill material could handle the rigorous demands of the 24/7, 365 playability of artificial turf sports fields was the next challenge. After three years of intense research and testing, one material met all the criteria necessary to become BrockFILL – America’s Southern Pine.

This dynamic, abundant, and marvelously durable resource held the promise of a fully sustainable artificial turf system without burdening tax payers with enormous cost hikes. It also achieved a dramatic cooling effect when compared to the traditional crumb rubber systems. But one of the most important moral accomplishments lies in the sustainability and sourcing of BrockFILL.

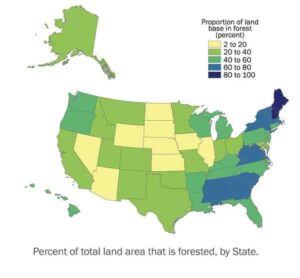

The logical source for raw material was found right here in the southern United States. The densest areas for forest land in America reside in the “Southern Region” ecoclimatic zone, which includes: Texas, Oklahoma, Louisiana, Mississippi, Missouri, Alabama, Georgia, Florida, Tennessee, Virginia, West Virginia, and the Carolinas. This region accounts for 13% of the entire world’s forests and has become the nation’s most valued agricultural crop, according to the South Carolina Forestry Commission. The massive economic resource has also increased by 10% since 1920 and has remained stable for the last 100 years despite 143% increase in population.

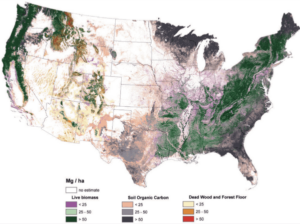

This Region has been able to sustain itself, and actually grow by 10%, through a combination of natural seeding and crop management. In the 1996-97 planting season alone 1,923,721 acres were planted in the south. Those trees have already produced at least two harvests and the third and final harvest will yield the eldest, tallest trees from those years. Depending on the forest management strategy and timber production, timber utilization contributes 25% to 85% of the overall reduction of CO2. The map below shows the leading mechanisms for CO2 storage by region. The areas attributing over 50% of their carbon stock to living biomass are predominantly found in the Southern Region ecoclimatic zone.

To unpack all that data, for a tree to grow a pound of wood, a tree consumes about 1.47 pounds of carbon dioxide and releases approximately 1.07 pounds of oxygen. Young, well-managed forests tend to be the most efficient at absorbing carbon dioxide and producing oxygen. Old, overcrowded, slow-growing forests begin to use more oxygen than they produce.

By harvesting the younger trees in 7-10 year intervals, tree farmers ensure a robust forest with the most effective air purifiers found in the Southern United States. They also ensure a stronger, more resilient gene pool for their farms.

The sustainable aspects of BrockFILL don’t stop at the farming stage. The parts of the tree that go unused during the nine-stage manufacturing process are then given to other mills near the BrockFILL plant to be used to make paper, wood pellets, mulch and many other products. BrockFILL is part of a larger lumber industry ecosystem where 98% of every tree harvested is utilized for some product.

When BrockFILL has reached the end of its useful life in a turf system it is then used as a soil amendment or mulch/ground cover – helping enrich soils for further plant growth. This end of life plan enables BrockFILL to avoid contributing to the global garbage problem, but actually helps reduce global CO2 emissions.

Every detail was carefully considered when bringing BrockFILL to the sports turf industry. From sourcing within the United States, to allocating uses for its byproducts, to finding a solution for its end of life, the Brock engineering team held true to the moral compass that guides Brock USA.