As environmental concerns become increasingly urgent, industries worldwide are adopting more sustainable practices. The artificial turf industry is no exception. Traditionally, artificial turf has faced criticism for its environmental impact, but recent advancements have shown a concerted effort by manufacturers to reduce their environmental footprint and move away from PFAS and microplastics, which are currently two major critiques of artificial turf. Here’s how the industry is stepping up to create more sustainable solutions.

- Adoption of Sustainable Materials

One of the most significant changes in the artificial turf industry is the shift towards sustainable materials. Turf Manufacturers are increasingly using recycled and recyclable materials in their products, along with organic and vegetal infills, as an eco-friendly alternative to traditional options. By doing so, the industry not only minimizes waste but also contributes to the circular economy, where materials are reused and recycled continuously. This transition also encourages innovation as manufacturers develop new techniques and technologies to efficiently incorporate these sustainable materials into their products. For instance, advances in material science are enabling the creation of turf fibers and backing systems that are not only made from recycled content but also designed to be fully recyclable at the end of their lifecycle. Furthermore, the major U.S. brands of artificial turf have made significant strides in sustainability by eliminating the use of PFAS in their manufacturing processes. With the recent ban on rubber and microplastic infills in the European Union, the push towards environmentally friendly alternatives like organic infills is becoming even more critical. These efforts not only reduce environmental impact but also help in setting new industry standards for sustainability.

- Energy-Efficient Manufacturing Processes

The production of artificial turf, shock pads, and infill can be energy-intensive. To mitigate this, manufacturers are investing in energy-efficient technologies and processes. This not only helps reduce the environmental footprint of production but also aligns with global efforts to combat climate change by lowering greenhouse gas emissions. Additionally, manufacturers are increasingly adopting renewable energy sources, such as solar and wind power, to run their production facilities. Integrating energy-efficient machinery and optimizing production workflows further enhance energy savings.

- Water Conservation

One of the key advantages of artificial turf over natural grass is water conservation. Natural grass requires extensive watering, especially in dry climates, which can strain local water supplies. Artificial turf, on the other hand, eliminates the need for regular watering. Some newer turf systems are also designed to optimize drainage and reduce water runoff, further enhancing their environmental benefits. Additionally, these advanced turf systems often incorporate permeable backing materials and innovative infill solutions that improve water infiltration and retention. This design helps manage stormwater more effectively, reducing the risk of flooding and erosion while replenishing groundwater levels. By minimizing water usage and enhancing water management, artificial turf can reduce the pressures on local water supplies, allowing more allocation for crops and other essential services. These benefits make artificial turf an attractive option for regions facing water scarcity and for organizations aiming to reduce their overall environmental impact.

- Enhancing Product Durability and Longevity

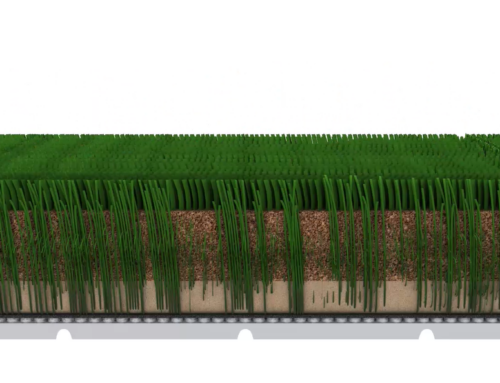

Durability is a critical factor in sustainability. Longer-lasting products mean fewer replacements and less waste. Manufacturers are focusing on creating more robust artificial turf that can withstand heavy use and harsh weather conditions. By enhancing the longevity of their products, they ensure that the turf remains functional and aesthetically pleasing for many years, thereby reducing the frequency of replacements and the associated environmental impact. Advanced materials and construction techniques are being employed to improve resistance to wear, UV degradation, and temperature fluctuations. For instance, the use of high-performance polymers and innovative tufting methods enhances the structural integrity and resilience of artificial turf. Additionally, manufacturers are conducting rigorous testing to simulate real-world conditions, ensuring that their products can endure heavy traffic and environmental stresses over extended periods. It’s known that using a shock pad below the turf extends the life of the field. This commitment to durability not only provides long-term value to consumers but also supports environmental sustainability by minimizing resource consumption and waste generation associated with frequent turf replacements.

- End-of-Life Recycling Programs

A significant challenge with artificial turf has been dealing with its end-of-life phase. However, the industry is making strides in this area by developing recycling programs. These initiatives aim to reclaim and recycle old turf, infill, and shock pads, transforming them into new products or repurposing them for other uses. This approach not only prevents turf from ending up in landfills but also promotes the sustainable reuse of materials. Advanced recycling technologies are being employed to separate the different components of artificial turf, such as backing, fibers, and infill so that each material can be processed and reused effectively. For instance, reclaimed turf fibers can be reprocessed into new turf or used in the production of other plastic goods. “The importance of companies developing end-of-life turf solutions in the US cannot be underestimated. Sustainable solutions like turf recycling are increasingly demanded by legislators, private equity investors, field owners, and other stakeholders,” said Tom Beck, VP of Recycling at The Recreational Group. By implementing these comprehensive recycling strategies, the industry is not only attempting to address the environmental challenges associated with artificial turf disposal but also conserve resources and reduce the demand for raw materials. At the end of the day, the goal is to recover and recycle materials at the same or lower cost than the cost of purchasing new materials.

However, achieving a completely recycled product from an old artificial turf field remains a challenging goal. The complex composition of artificial turf, which includes various types of plastics, infill materials, and backing layers, combined with years of environmental exposure, makes it difficult to reclaim and repurpose all components efficiently. One cannot simply recycle an old turf field and get a whole new field in its place. This means that while some materials can be reclaimed and reprocessed into new turf products, a substantial portion of the original field still requires new, virgin materials to achieve the necessary performance and durability standards. As explained by journalist Lisa Song in her ProPublica article, “With mechanical recycling, it’s hard to make plastic that’s 100% recycled; it’s expensive to do, and the process degrades plastic. Recycled pellets are often combined with new pellets to make stuff that’s 25% or 50% recycled, for example.” A recent paper published in the Journal of Rubber Research, “Comparison of Degradation Effects for Three Types of Crumb Rubber Used on a Sport Surface,” [1] documented the degradation of crumb rubber over time and its loss of performance. Reusing old rubber in a new field does not result in the kind of performance and durability that owners expect from a new field. This challenge underscores the need for continued innovation and improvement in recycling methods within the industry to increase the proportion of reclaimed materials and enhance the overall sustainability of artificial turf fields. One final note on turf recycling to put things in perspective: according to the EPA, in the U.S., there are 71.4 billion lbs/year of plastic waste generation, and with an estimated 1,800 artificial turf fields produced annually in the U.S., this accounts for only about 0.11% of the total U.S. plastic waste generation.

- Compliance with Green Certifications

To ensure that sustainable practices are standardized and recognized, many artificial turf, shock pads, and infill manufacturers are seeking green certifications. In Europe, a new chain of custody and material monitoring software will soon be launched to help manufacturers assess the environmental footprints of their products and identify opportunities for improvement. Currently, certifications such as Cradle to Cradle, LEED, USDA BioPreferred, and others set stringent criteria for environmental responsibility. By adhering to these standards, manufacturers demonstrate their commitment to sustainability and provide assurance to consumers that their products meet high environmental standards. Pursuing these certifications involves comprehensive assessments of a product’s lifecycle, including material health, product reuse potential, renewable energy use, water stewardship, and social fairness. This rigorous process encourages and rewards manufacturers to innovate and improve their practices continuously.

For example, achieving LEED certification can involve optimizing energy performance, using sustainable materials, creative stormwater management, and improving indoor air quality, all of which contribute to the broader goals of reducing carbon footprints and promoting sustainable development. Such is the case for Casey Middle School in Boulder, Colorado, which achieved LEED Platinum certification on their school construction project, partly because of the unique and innovative stormwater management system under the artificial turf field. Civil Engineer Matt Oscamou, PE, from Oak Creek Engineering, and designer for the site work at Casey (with JVA Consulting Engineers) explained, “LEED ultimately has the opportunity for innovation credits, so if you’re doing something unique to improve the environmental condition on the site, like a unique stormwater management system, you can present a rationale for additional ‘innovation’ credits that can supplement the score and help push the project to platinum certification.” Moreover, displaying these certifications helps manufacturers build trust with environmentally conscious consumers and stakeholders, showing transparency and accountability in their sustainability efforts. This not only boosts the brand’s reputation but also drives the industry as a whole towards more sustainable and responsible practices.

Ongoing Research and Innovation

Sustainability is an evolving journey in virtually every consumer and industrial product, and the artificial turf industry is continually researching and innovating to reduce its environmental impact. This includes exploring new materials, enhancing production processes, and developing more efficient recycling methods. Collaborative efforts between manufacturers, research institutions, and environmental organizations are driving these advancements. For example, joint research projects are further investigating the use of plant-based polymers and biodegradable compounds that could revolutionize turf production. Meanwhile, improvements in manufacturing, such as the adoption of low-energy and low-emission technologies, are reducing the carbon footprint of turf production. This pursuit of innovation further pushes the artificial turf industry to become an active participant in environmental stewardship, offering products that are both high-performing and eco-friendly.

Citations:

- Bridge, J.W., Yeung, C.H., Ginos, J.E. et al.Comparison of degradation effects for three types of crumb rubber used on a sport surface. J Rubber Res27, 529–540 (2024). https://doi.org/10.1007/s42464-024-00270-6