Wood has been part of mankind’s evolution for millennia. Thirty-one percent of the planets’ surface is covered by forests, so it’s no wonder that this amazing natural material has been used by man since the dawn of our existence. From the fires that kept us warm and cooked our food, to the log cabins that sheltered us, to the ships that crossed the oceans. After centuries, wood continues to play an important role in our lives.

“Finding a way to make wood work as an infill for artificial turf was an elegant solution to a 25-year-old problem,” says Steve Keys, COO at Brock USA. “We use wood every day. To build our homes, baby toys, play sets, bowls and plates, cooking utensils, and in so many other ways. So we knew from a human health perspective, it was a safe raw material.”

As the artificial turf industry has searched for an alternative to the scorching hot temperatures caused by crumb rubber, wood has emerged as the most effective solution. There are several key benefits to wood as an infill: It’s organic so there is no hazardous waste at the end of the turf’s life, it’s an abundant, renewable resource that is sustainably grown and harvested in the USA. It’s incredibly durable when engineered properly, and it’s affordable since there are already large industries, such as the paper, biofuels and animal industry that use huge quantities already. In the development of BrockFILL, Brock USA leveraged the supply chain of these industries and engineered the process to make an affordable, quality wood infill.

Wood is also excellent in the infill application due to its natural resistance to UV degradation. Fences, house siding, and other outdoor uses with constant UV exposure last for decades, far longer than artificial turf will last. Wood is also a wonderful material for its malleability. Think about all the uses and the different forms it comes in. In furniture, it’s curved, colored, smoothed, tailored and strong. Wooden toys for children are preferred to plastic towards the growing health conscious population. Most parents know that Thomas the Tank Engine and wooden building blocks are safe for their kids! Musical instruments, boats, outdoor gardens where we grow our vegetable, and the list goes on and on.

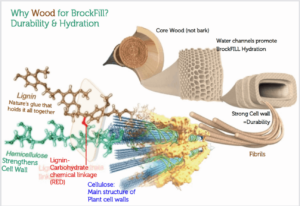

BrockFILL wood particles also have a quality that makes it ideal for artificial turf. They are hydrophilic,, meaning they like water. So during a rainfall or even condensation in humid climates, they absorb natural moisture. When the water source stops, they slowly release the water through evaporation. This keeps the field cool for days even without additional water. Since the material absorbs water, they also gain weight and stability so they don’t float like other materials such as cork. (Cork is hydrophobic meaning it repels water which is why cork is used for wine stoppers and flotation devices.)

During snowfall and freezing temperatures, all fields freeze regardless of infill. However, because moisture is retained in BrockFILL, the thawing time for the field, generated by the heat gain in the artificial turf fibers, will most likely be longer than a field with Crumb rubber. An artificial turf field with BrockFILL will probably fall between a natural grass field and an artificial field with rubber when it comes to thawing time. However, since there is a shock pad below the turf, impact absorption will still occur.

BrockFILL uses wood in its pure form, without coatings that can come off, or blending with other materials that would negate its sustainable benefit. But to be used as an infill, the wood needed to be chipped, dried, sorted for particle size, conditioned, de-splintered, and smoothed to meet the desired performance criteria. But in the end, it’s just one material. Its purity is what makes it special.

The basic structure of wood is what makes it strong. Brock

FILL achieves a specific grain orientation during processing. Without that grain orientation you end up with sawdust. The proprietary processing of BrockFILL results in an infill that is incredibly durable. A method called particle size distribution, which measures the particle sizes before and after wear testing, shows virtually not change after 8-10 years of use, and virtually the same particle sizes as brand new crumb rubber.

Most people think wood molds and rots. And that’s true if wood is in the presence of nature‘s normal biological activity that occurs on soils. But artificial turf is a virtually sterile environment. Below BrockFILL is a layer of sand, then plastic backing of the turf, then the shock pad, then a stone base free of organics. So biological activity is eliminated. But at the end of the turf life, when BrockFILL is used as a soil amendment for natural grass, it is returned to the normal soil conditions that promote decomposition. This is the same reasoning behind why fences last so long. They are off the ground and not subject to biological activity. Taking advantage of the lack of biology in artificial turf made wood an ideal solution.

Pine wood is also very low on the allergen scale. Although wood pollen can create irritation during allergy season, and some people have allergies to pine nuts, neither of these components exist in BrockFILL. Even the idea of prolonged exposure to fine wood dust causing cancer, such as an employee in a lumber mill working for decades without a mask, is now debatable. But since BrockFILL is a clean, durable particle that does not contain or produce dust, these concerns do not apply. After all, children have been playing on engineered wood fiber playgrounds safely for decades.

Wood also plays an important role in our economy. The state of GA alone is growing 50% more trees today than were grown in 1950, realizes $35 billion in economic impact and creates 144,000 jobs. This is the result of the conversion of difficult to farm land into forests of southern pine, the predominant wood used in fuel pellets, animal bedding and for the paper industry. And now BrockFILL. Yet despite the size of the artificial turf market, it is dwarfed by these other uses, so using wood as an infill does not increase the demand for trees.

Wood has been and will continue to touch our daily lives. And now it brings its benefits to an industry that needs a solution to the scalding temperatures, disposal, and micro-plastics issues caused by crumb rubber infill. Attention to the health and safety of our athletes is a growing concern. Attention to the health of our planet is of paramount importance. Now artificial turf can take the natural evolutionary step by replacing crumb rubber with an essential component that is good for people, and good for the planet.